InUse

Company profile:

Founded in 2015, InUse’s SaaS industrial IoT software is designed for industry and aims to help production sites lower their environmental footprint while optimising their performance.

The key role played by industrial manufacturers in helping production sites’ digital transformation

Production sites are increasingly turning to digital and IIoT platform solutions in a bid to improve performance and reduce environmental impact: a golden opportunity for industrial manufacturers to provide their clients with tangible solutions while speeding up their transitioning towards Equipment As A Service.

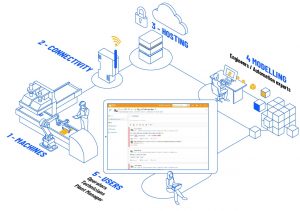

With this in mind, the InUse platform allows equipment manufacturers to connect their machines and offer a range of digital services in a matter of months.

As well as supporting industrial sites in improving their eco-efficiency, this transition also gives equipment manufacturers the opportunity to:

- deepen customer relationships

- stand out from the competition

- increase service-related revenue

Increase your industrial performance by connecting your equipment

The remote measurement and analysis of industrial performance is one of the most highly anticipated use cases among manufacturing companies. This use case, confirmed by a recent report by IoT Analytics (IoT Use Case Adoption Report), is a standard use case of our platform. It is the first and indispensable step on the path to operational excellence. It lays the foundation for resolving the most complex issues.

The remote measurement and analysis of industrial performance is one of the most highly anticipated use cases among manufacturing companies. This use case, confirmed by a recent report by IoT Analytics (IoT Use Case Adoption Report), is a standard use case of our platform. It is the first and indispensable step on the path to operational excellence. It lays the foundation for resolving the most complex issues.

Digital twin technology : game-changing potential for factories

The increasing use of industrial IoT solutions gives manufacturers the ability to create digital representations of how their production processes work, while measuring and tracking their continuous improvement processes in a digital twin model. In addition, Artificial intelligence is making equipment capable of steering production teams towards taking better decisions. This two-pronged approach simultaneously speeds up knowledge-sharing processes in a production setting and roll-out of continuous improvement cycles, such as PDCA and DMAIC.

The increasing use of industrial IoT solutions gives manufacturers the ability to create digital representations of how their production processes work, while measuring and tracking their continuous improvement processes in a digital twin model. In addition, Artificial intelligence is making equipment capable of steering production teams towards taking better decisions. This two-pronged approach simultaneously speeds up knowledge-sharing processes in a production setting and roll-out of continuous improvement cycles, such as PDCA and DMAIC.